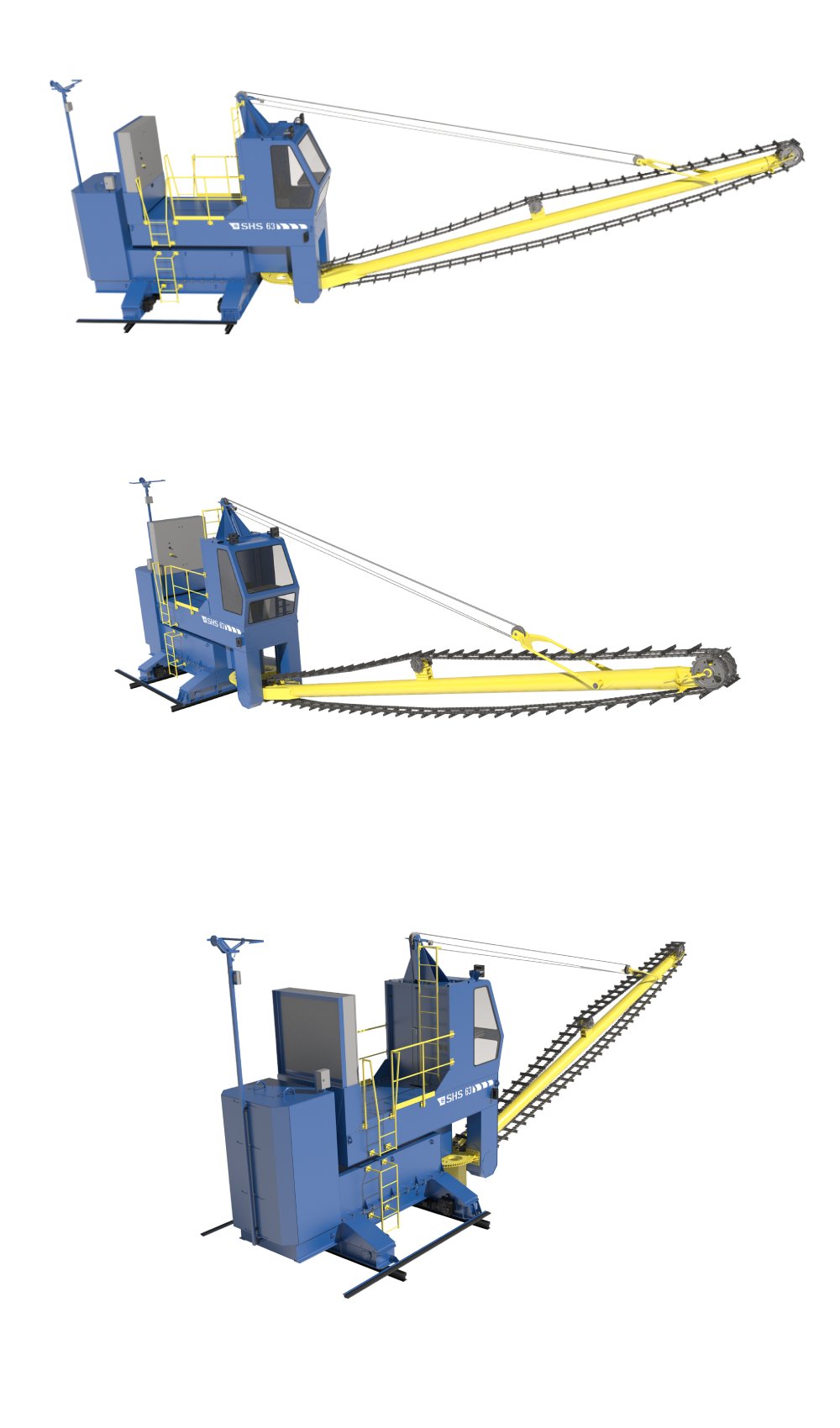

SHS 63 RAKING MACHINE

The special SHS 63 raking machine is designed for handling glass raw materials in glass works. After some modifications, it may be used for handling similar materials.

DESCRIPTION

The raking machine consists of a bogie undercarriage for use on rails, a lower frame, a counterweight, a rotating upper frame with the operator’s cabin, and the rake arm, which carries the moving raking chain with rakes. The rake arm is suspended from one end by wire cables from the upper frame of the machine and routed over a pulley at the other end. The angle of inclination of the rake arm is be adjusted by winding the wire cables on the winch. Electric motors are used to move the machine and its individual parts. Electric power is drawn from an overhead contact line. Sensors monitor the positions of the machine and its parts.

Function

The machine moves longitudinally on the rails in the storage hall containing the stored material. The raking chain with rakes pushes the glass raw material from the pile onto a grate under which a belt conveyor is positioned parallel to the rails along the entire length of the storage hall. The belt conveyor transports the raw material for further processing.