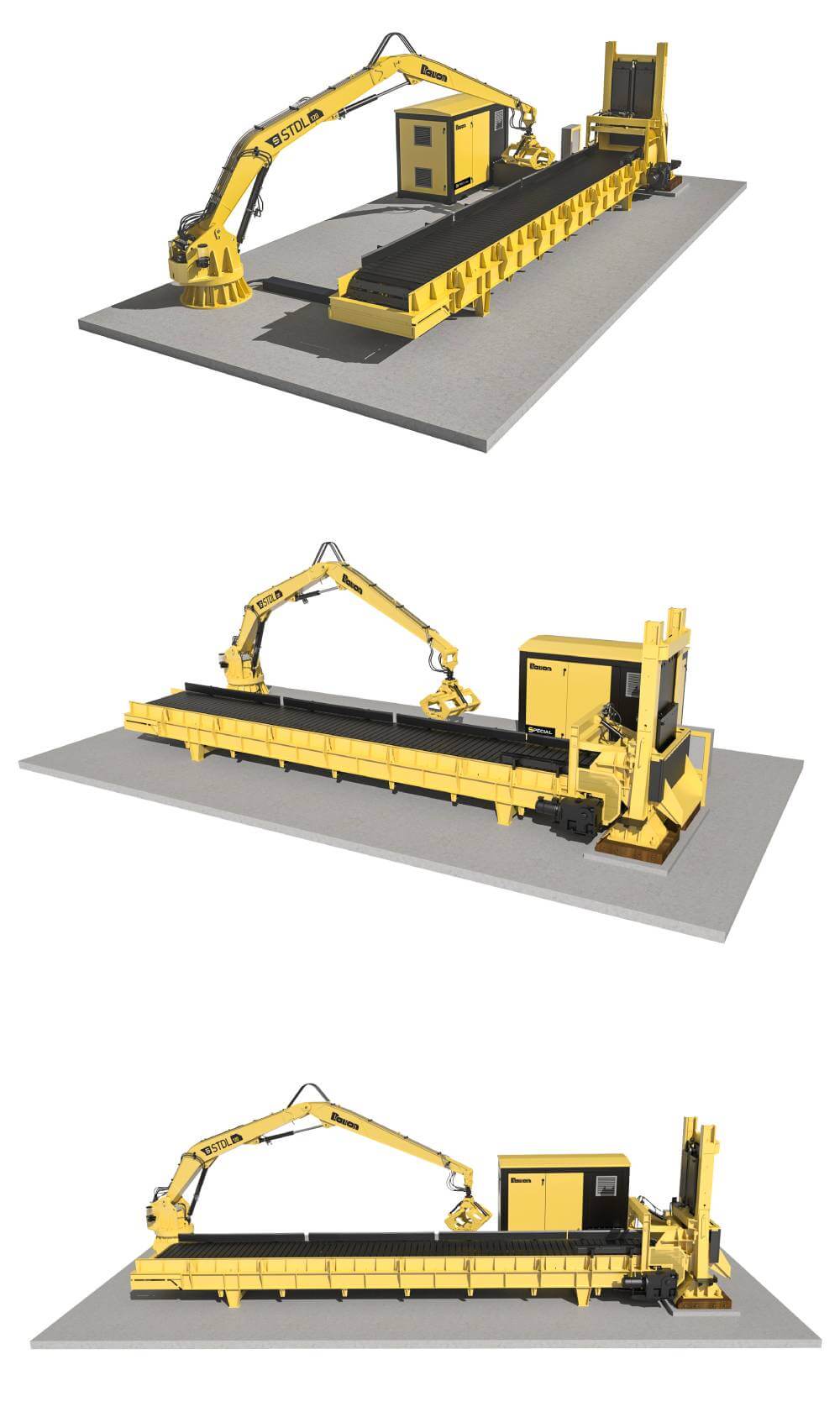

STACIONARY CRUSHER LINE STDL 120

DESCRIPTION

This stationary crusher line is designed for crushing concrete panels. The line is composed of four basic modules:

- tray feeder DP-1200/1400

- slab crusher DD-65/1400

- hydraulic unit HA90R-LS

- handling unit RK4095-G

Concrete panels are loaded on the feeder conveyor using the grab on the boom arm of the handling unit and the conveyor continuously feeds the panels into the crusher. The crusher is made of a frame in which a main working surface weighing up to 6210 kg is moved in a vertical direction, driven by a hydraulic system upward, at which it point it is released at the upper apex and its inherent weight drives it downward against a stationary anvil, breaking and crushing the concrete slabs on contact, until the cycle repeats. The crushed material is removed for further processing, which leads to the separation of the crushed concrete and the steel rebar.

The entire line is powered by a dedicated hydraulic system.