HDS 03

HYDRAULIC LOG GRAB

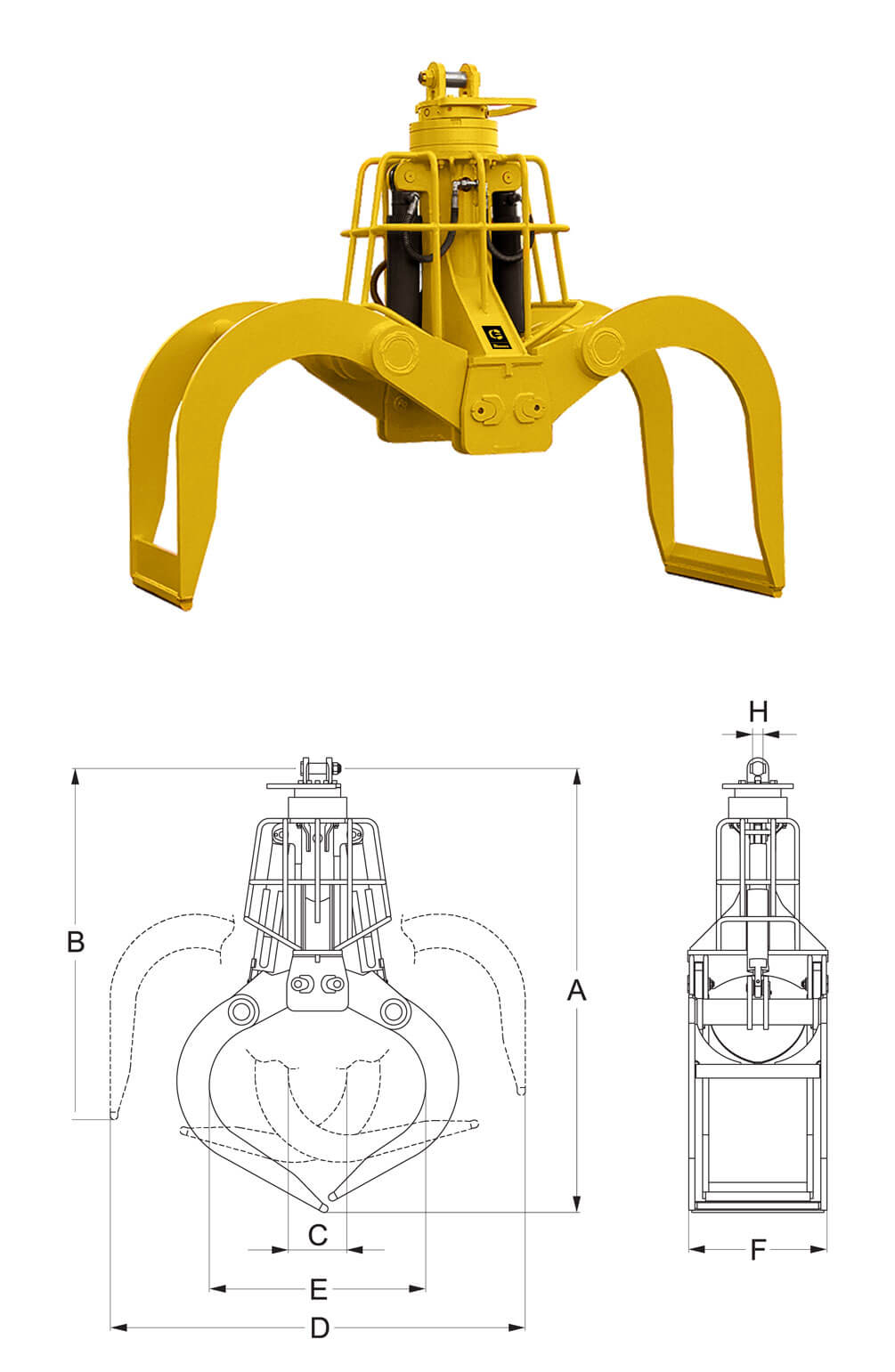

MODEL DESCRIPTION

Hydraulic log grab in a claw design. This design allows logs to be gripped precisely along their axis. There is no need to take a full grab as the claw mechanism design permits overlapping as shown in the technical drawing shown at the bottom of this parameter sheet.

The basic model grab is delivered with a reliable hydraulic rotator, which is integrated into the upper part of the carrier.

The load rating of the excavator in all working directions using this implement is key in selecting the right grab and carrier assembly.

STANDARD CONFIGURATION

- with 360º hydraulic rotation (max. 200 bar);

- HARDOX 400 jaws,

- HARDOX 500 blades;

- special storage cases;

- all connecting pins are made from a special high-strength alloy with surface hardening;

- covers over hydraulic cylinder rods;

- jaw design ensuring proper gripping along the axis.

CUSTOM OPTIONS

- fixed mount (not rotating) (72 kg lighter);

- option to mount on a swinging brake;

- special covers to prevent mechanical damage;

- HARDOX 400 blade tip spars to protect the underlying material (wagon beds);

- delivery with universal carrier to mount to any machine.

| Recommended carrier rating | 10.0 – 20.0 | [t] |

| Maximum load capacity | 4.0 | [t] |

| Maximum working pressure | 320 | [bar] |

| Grab | configuration | |